An ISO 9001:2008, 14001:2004, 10002:2014, 13485:2016 & WHO-GMP, CE, BIS Certified Company

METALLOGRAPHY EQUIPMENT

Belt Polisher RBP-100

Belt Polishers : For flat, Coarse grinding prior to fine grinding. The specimens to be ground in 60, 80 or 120 grit after cutting operation or moulding to remove surface imperfections. Useful step to remove light metallurgical damage in the specimen surface induced during cut-off operation.

Belt Polishers : For flat, Coarse grinding prior to fine grinding. The specimens to be ground in 60, 80 or 120 grit after cutting operation or moulding to remove surface imperfections. Useful step to remove light metallurgical damage in the specimen surface induced during cut-off operation. Belt Surface Grinder RBPD-32 Series

Technical Specifications:Distance between two rollers :- 255 mm

water cooling system and dust separation plant

water cooling system and dust separation plantBelt :- 100mm width x 1000mm length

Rotation :- 1400rpm

Surface speed :- 760rpm

Motor :- 750W

Power :- 380V/50HZ

Dimension :- 580x600x980mm

Grinding Size :- 220x120mm .

Digital Hot Mounting Machine RHM-2 Series

Automatic metallographic specimen mounting presses a kind of full automatic mounting press, equipped with in-out water cooling system. It is suitable for the heat mounting (thermohardening & thermoplastic) for all kinds of materials. After the parameters such as heating temperature, heat preserving time and applied force etc. are set up, put the specimen and mounting material into the machine, close the cover and press the start button, then the machine will finish the job automatically. It is not necessary for the operator to be on duty. According to different requirements of the material, there are four kinds of moulds that can be chosen to meet the demands at will. Also it is available to prepare two pieces of specimens at the same time, the capacity is doubled.

Technical Specifications:

Diameter of specimen :- 30mm

Cooling method :- water cooling

Max. power consumption :- 1000W

Temperature setting range :- 0-300°C

Net weight :- 60Kg

Power supply :- 650W 220V, 50Hz

Dimension :- 570 × 520 × 670 mm

Fully Automatic Hot Mounting Machine RHM-5 Series

Automatic metallographic specimen mounting presses a kind of full automatic mounting press, equipped with in-out water cooling system. It is suitable for the heat mounting (thermo hardening & thermoplastic) for all kinds of materials. After the parameters such as heating temperature, heat preserving time and applied force etc. are set up, put the specimen and mounting material into the machine, close the cover and press the start button, then the machine will finish the job automatically. It is not necessary for the operator to be on duty. According to different requirment of the material, there are four kind of moulds that can be chosen to meet the demands as per requirement. Technical Specifications:

Technical Specifications:Diameter of specimen :- Ø25mm, Ø30mm, Ø40mm, Ø40mm, Ø50mm

Cooling method :- Water cooling

Power Supply :- Single phase, 220V, 50Hz

Max. power consumotion :- 1800W

Setting range of system pressure intensity :- 0-2Mpa

Temperature setting range :- 0-300°C

Heat preserving time :- 0-99m-99s

Dimensions :- 615x510x500 cm

Net weight :- 110kg

Hot Mounting RHM-25 Series

Hot Mounting Press is designed user friendly for efficient and quality production of the specimen mounts. The Press has rigid construction complete enclosed body and elegant look. Design of the heater, operation ease, good quality hydraulic integrated jack. One can produce absolutely consolidated embedded single specimen mount with good finish, out of this mounting press. This machine has manual operation with lever.FEATURES:- Higher results in measuring Image Analyses study. Temperature controller for setting heat cycle.

Timer System for completion of process. Thermocouple Inside for indication of heat produce.

Timer System for completion of process. Thermocouple Inside for indication of heat produce. TECHNICAL DETAILS -: Product Metallurgical Hot Mounting Press

Operation :- Manual with lever

Mould Diameter :- 25 mm

Heater :- 750 Watts

Hydraulic Jack :- 6-8 Tons

Thermocouple :- 1 No.

Temp. Range :- 0-300° C

Manual Hot Mounting Machine RHM-30 Series

Metallographic inlaying machine is is suitable for cutting general metallography and lithofacies material specimens. This machine features safety & reliable performance, low noise and easy operation. It is the ideal instrument for specimen preparing purpose used in colleges, laboratories and factories.

Technical Specifications:-

Mould Diameter:- 30mm

Heat Specifications:- =800W

Temp. Adjustment Range:- 0-400°C

Power:- Single Phase 220V 50Hz

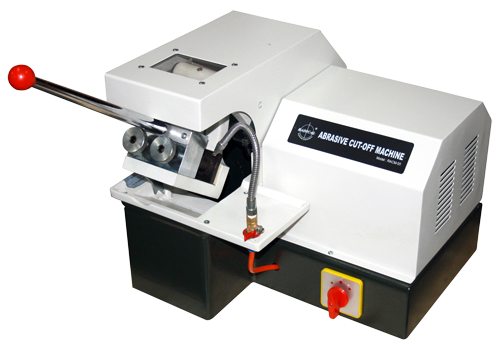

Abrasive Cut Off Machine RACM-55 Series

Metallographic Specimen Cutting Machine can be used to cut various metal or non-metal specimens (select different cutting disc according to different materials) so as to observe the Metallographic and lithofacies structure. The machine features high performance, low noise and high finish of specimen cutting sections, etc. The machine has nice appearance and it is easy to oprate safely and reliably. It is the ideal and nacessary specimen preparation instrument used in factories, scientific research institutes and colleges etc.

Technical Specifications : -

- Maximum Cutting Section:- 55mmx55mm

- Abrasive Wheel:- 300x2x32mm

- Rotating Speed:- 2800 rpm

- Motor:- 2.2kw

- Power Supply:- 3 phase, AC 380V 50Hz

Abrasive Machine RACM-80 Series

Sturdy Floor Model Cutter for sectioning metals ceramic and mineral samples- Cutting capacity upto 80mm

- Spindle Speed 2000r.p.m. and cut-off wheel dia-12".

- 7.5HP, 3 Phase Motor.

- Cooling with high flow water jets to provide optimum cooling.

- Re-circulation coolant tank with 20 ltr. Capacity.

- Swivel Type Self Centering Steel Wise.

- X & Y Movement.

- T-slot bed.

- Lighting facility in working area.

Abrasive Cut Off Machine RACM-80 Series

Abrasive Cut off machine is equipped with big cutting room and movable T shape work table. There for this machine has the ability of cutting rectangle and large specimens.Also the equipped separate type vice is very convenientfor operator to clamp various heterotypic work pieces.Technical specifications:-

Various cutting data can be displayed on high definition backlight type LCD screen.

Cutting diameter:- 80mm

Equipped with 60L cooling liquid water tank.

Non-burning loss swing type cutting means that improved the cutting quality

Automatic withdraw function after cutting is finished

Automatic withdraw function after cutting is finishedBidirectional feeding means increase the length of deep cutting

Cutting speed:- 2.25, 3, 4, 5, 7, 9, 12, 15mm/min.

Cutting Disc rotating speed:- 2100rpm

Cutting Disc specification:- 350 x 2.5 x 32mm

Display:- LCD with high resolution backlit dot matrix

Power:- three phases with four cables, 380V, 50Hz.

Dimensions:- 930 x 700 x 610mm

Net weight:- 220 KG

Abrasive Cut Off Machine RACM-4 Series

The machine is suitable for cutting general irregular metallurgical sample materials in order to observe the material microstructure. This machine adopted by double cover fully enclosed structure. It guarantees to cutting samples under absolute security condition. Equipped cooling system can clear up the heat produced during cutting so that it will avoid the metallographic structure deforming of specimen because of heating influence. It is the necessary specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

| Max cutting section | - | 65mm |

| Grinding wheel | - | 250X1.5X32mm |

| Motor | - | 1.5kw |

| Rotating speed | - | 2800r/min |

| Power supply | - | 380V,50Hz |

| Dimension | - | 990X610X1300mm APPX |

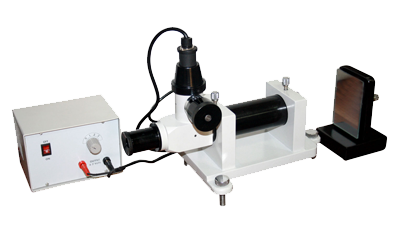

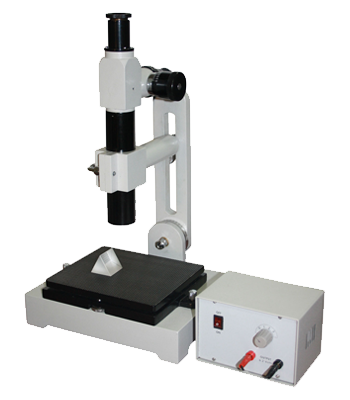

Auto Collimeter

AUTO COLLIMATOR is a sensitive, extremely accurate optical instrument which is precisely used in optical workshops, inspection departments and quality control labs.

It is basically a comparator where we compare optical element like slabs and prisms for flatness.

It is used for very small angle measurements of the order of minutes.

Specifications : -

Specifications : -

Specifications : -

Specifications : -

- Main Drum Division = 2 second

- Division on Reticle = 1 minute

- FL of Objective = 220mm

- Clear Aperture = 40mm

- Magnification = 11x

- Least Division on = 2" of arc Micrometer Drum

- Built in light source ,With 3 levelling screws in the base and suitable for measuring small angles Widely used in Metrological labs. It work on the principle light fall normally on mirror, the reflected ray comes back along the same path as the incident.

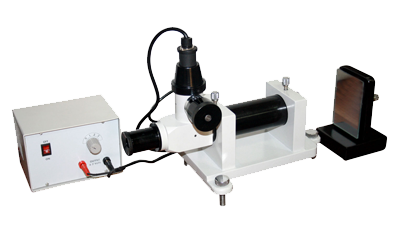

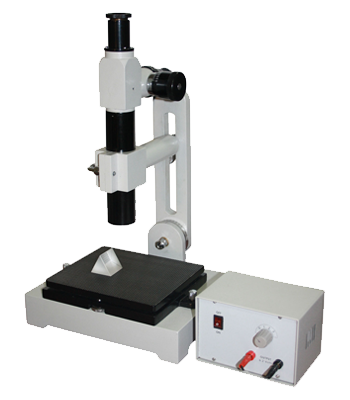

Angle Dekkor

'RADICAL' Precision Angle Dekkor is sensitive extremely accurate optical instrument which is precisely used in optical workshop. Inspection department and quality control labs.

APPLLICATIONS: It is basically a comparator where we compare optical elements like slabs

and all types of prisms for flatness and angles of prism in vertical plane

respectively. It is used for very small angle measurements of the order of

seconds.

APPLLICATIONS: It is basically a comparator where we compare optical elements like slabs

and all types of prisms for flatness and angles of prism in vertical plane

respectively. It is used for very small angle measurements of the order of

seconds.

Specifications : -

APPLLICATIONS: It is basically a comparator where we compare optical elements like slabs

and all types of prisms for flatness and angles of prism in vertical plane

respectively. It is used for very small angle measurements of the order of

seconds.

APPLLICATIONS: It is basically a comparator where we compare optical elements like slabs

and all types of prisms for flatness and angles of prism in vertical plane

respectively. It is used for very small angle measurements of the order of

seconds.Specifications : -

- Focal Length of Objective : 220mm

- Clear Aperture of Objective : 40mm

- Magnification : 11X

- Measuring Range : 60-0-60 minute in X-Y axis.

- Least Division on Reticle : 1 minute of arc

- Least Division with Micrometer Drum : 2 second of arc

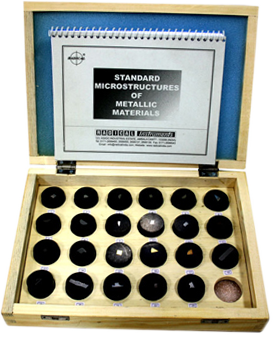

Standard Samples of Metal Structure

|

|

A Set Consists of 23 Standard Samples Which Covers The Entire Range I.E.

| Sample No. | Title | Sample No. | Title |

| 1. | Dead Mild Steel | 13. | Mottled Cast Iron |

| 2. | Low Carbon Steel | 14. | Ductile Cast Iron |

| 3. | Medium Carbon Steel (Annealing) | 15. | Cartridge Brass |

| 4. | Medium Carbon Steel (Normalizing) | 16. | Muntz Metal |

| 5. | Decarburised High Carbon Steel | 17. | Tin Bronze |

| 6. | Inclusion in Steel | 18. | Electroplated Component |

| 7. | Hardened Steel | 19. | Anodised Aluminium |

| 8. | Tempered Steel | 20. | Fusion Welded Mild Steel |

| 9. | Carburised Steel | 21. | Friction Welded Steel |

| 10. | Tool Steel | 22. | Powder Metallurgy Component |

| 11. | Grey Cast Iron | 23. | Deformed Mild Steel. |

| 12. | White Cast Iron |

Complete information including chemical composition, mechanical treatment, details of heat treatment, type of Etchant with description of Microstructure along with their coloured photographs are provided in a booklet. These sets are supplied in a wooden storing box with silica gel.